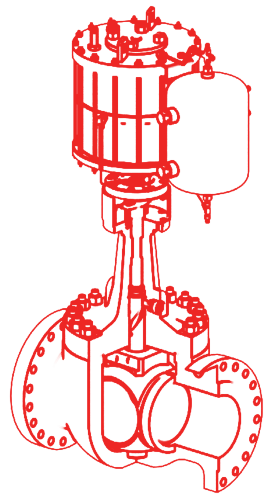

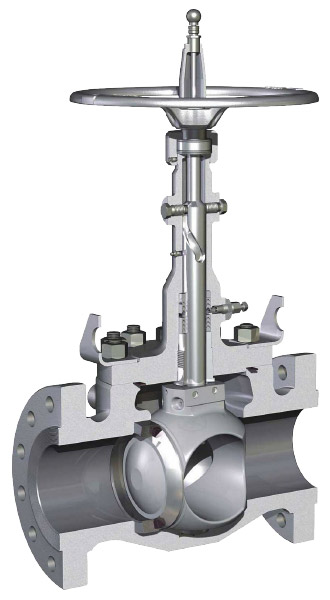

Rising Stem Ball Valves

Ideal for applications that require zero leakage and frequent operation

To See More Details Download Catalog Below:

No Rubbing Between Sealing Surfaces

The tilt-and-turn action eliminates seal abrasion, Which is the major cause of seat Wear in conventional Ball, Gate and plug valves.

Injectable Packing

For in-services maintenance, stem packing material Is injected through the packing fitting, giving complete Control of fugitive emission. (Available on all enclosed bonnet models.)

Single- Seat Design

The single, stationary seat in the ORBIT valves Seal in both direction And avoids the problem of trapped pressure between seals.

Long Life

ORBIT valves replace troublesome Ball valves, Gate valves, Globe Valves and Plug Valves. The ORBIT design has Performance advantages that reduce plant outage And reduce the Cost of ownership.

Optimum Flow

Full port or reduce port Openings Give high Cv Figures. System pumping efficiency is enhanced And Erosion problems are reduced.

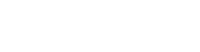

Top-entry Design

In-line inspection and repair, after system Depressurizing, simplifies maintenance.

Dual Stem Guides

Hardened stem slots and tough guide pins Control the lift-and-turn action of the Stem.

Self-Cleaning

Tilting the core away from the seat before rotation causes Immediate flow around 360 degrees of the core face. Product Flow flushes any foreign material away from the seat without localized, high velocity erosive flow.

Low-torque operation

ORBIT valves turn easily because seal rubbing is eliminated.

Wear-resistance Hard facing on Core

The Core face is hard, polished material that will endure difficult service, without loss of sealing integrity.

Mechanical Cam Closure

The Cam angle at the lower end of the stem provides a mechanically energized seal.

• Note: Never remove any part from and ORBIT valve unless specifically instructed to do so in the literature, or without first consulting a Cameron representative. Incorrect Procedure could result in personal injury and/or property damage.

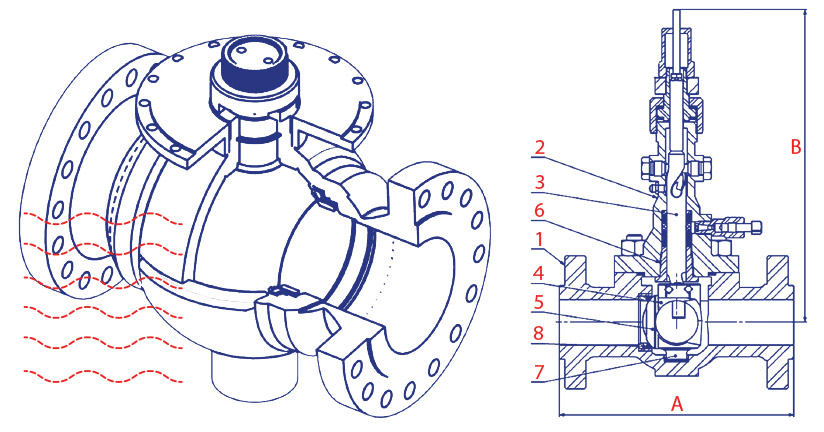

GAZAR Rising Stem Ball Valve (Single Seat)

Specifications: Top Entry (2 Pieces) | Flanged Ends Full Port | Trunnion mounted | One piece stem valves, enclosed bonnet

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | API608 / API6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Safe Design | API607 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Class 150, 300 & 600

Size (inch)

size |

|---|

1’’ H |

1 1/2’’ H |

2’’ H |

3’’ H |

Socket Weld

A | B | Weight (Kg) |

|---|---|---|

159 | 400 | 23 |

184 | 443 | 23 |

216 | 448 | 25 |

295 | – | 64 |

Threaded

A | B | Weight (Kg) |

|---|---|---|

159 | 400 | 23 |

184 | 443 | 23 |

216 | 448 | 25 |

295 | 651 | 64 |

Class 900

Size (inch)

size |

|---|

1’’ H |

2’’ H General |

2’’ H O.S.&Y |

3’’ H |

Socket Weld

A | B | Weight (Kg) |

|---|---|---|

159 | 400 | 20 |

284 | 552 | 41 |

248 | 552 | 41 |

– | – | – |

Threaded

A | B | Weight (Kg) |

|---|---|---|

159 | 400 | 20 |

216 | 483 | 25 |

270 | – | 32 |

295 | 651 | 64 |

* 1 inch (25 mm) size valves have single stem guide. ** H: Hand wheel operated *** G: Gear Box operated

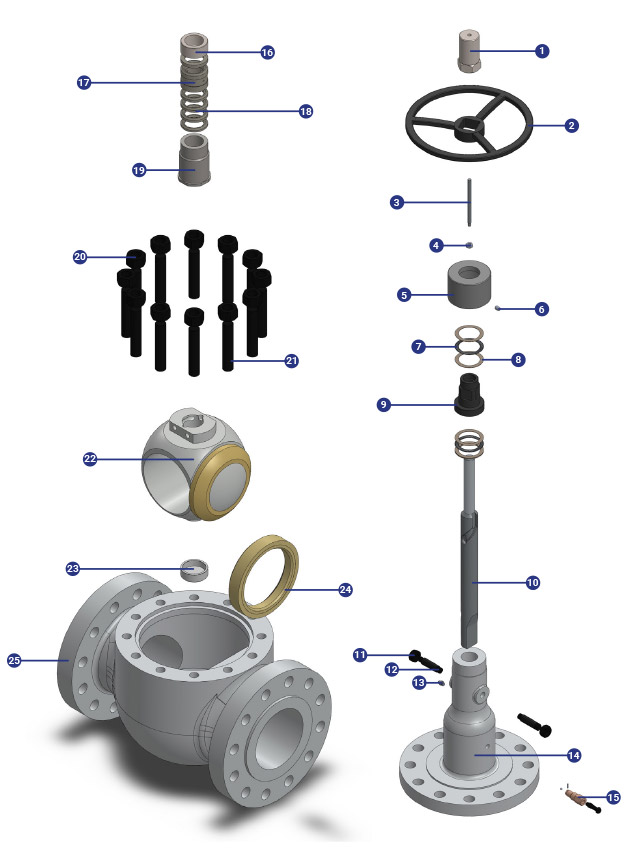

- Stem Protector

2. Handwheel

3. Position Indicator Rod

4. Position Indicator Rod Nut

5. Bonnet Nut

6. Set Screw

7. Needle Bearing

8. Bearing Race

9. Drive Nut

10. Stem

11. Stem Guide Nut

12. Stem Guide

13. Grease Nipple

14. Bonnet

15. Packing Fitting

16. Packing Chamber Bushing

17. Lantern Ring

18. Packing Ring

19. Bonnet Bushing

20. Body Stud Nut

21. Body Stud Bolt

22. Core

23. Trunnion Bushing

24. Seat Ring

25. Body