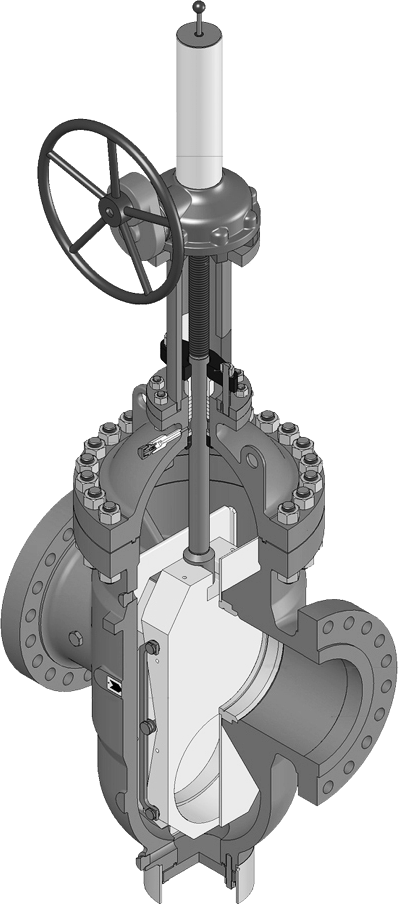

Through Conduit Gate Valve

For on/off, ESDV (Emergency Shutdown Valve) and HIPPS (High Integrity Pressure Protection System) valve applications

To See More Details Download Catalog Below:

About Through Conduit Gate Valves

Through Conduit Slab Gate Valves can be used in many applications. Our valves have been installed in numerous projects around the world, in on/off, ESDV (Emergency Shutdown Valve) and HIPPS (High Integrity Pressure Protection System) valve applications. Designing for increasing maximum allowable pressures for Slab Gate Valves, through continuous research and development to meet our clients’ new requirements, is one of our major objectives. The resulting design expertise guarantees the product reliability improvement year by year.

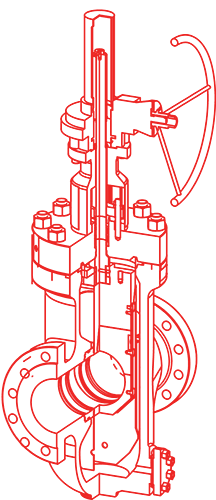

Seat Sealing

Slab gate valve construction includes spring energized floating seats, which provide positive Seating on both sides, regardless of upstream or downstream pressure conditions. The seat seals are spring energized to ensure sealing under low pressure conditions. When the line pressure increases, the seat-to-gate contact pressure increases accordingly to provide positive shutoff. Since both seats are individually energized by differential pressure across the seat itself, the valve cavity can be vented when the upstream and/or downstream side is pressurized. The valve exhibits identical performance, regardless of direction of flow, and/or orientation of differential pressure. Different solutions are available for seat-to-body gaskets, depending on Service fluid type, pressure, and temperature conditions.

Acting design

The Through Conduit Slab Gate Valve is designed and manufactured with the rising stem to accommodate the floating movement of the gate. During the valve operation, the line fluid fills the Bore cavity. The fluid pressure in the bore cavity generates a vertical force on The stem that pushes the trim from bottom to top. In case of emergency, This force is used to assist the actuator spring to bring the valve gate to the required Failure mode position.

Design feature

S.M.P Co manufactures a full range of though conduit gate valves for production, processing and transmission applications. Though conduit gate valves provides superior bubble tight sealing capabilities in gas service and unmatched robustness in harsh services With high pressure, high temperature and sand service. GAZAR can supply Through Conduit Gate Valves in different configurations, slab type and double expanding type. GAZAR through Conduit Gate Valves comply with following industry standards:

Special Features

NACE Requirement

Negligible pressure drop

Pig ability

Special Bore

Back Seat

Full/partial cladding

Equalizing hole in gate

Extended Stem

Double Block & Bleed

Ad hoc design for horizontal stem

installation and or vertical pipeline

Ad hoc engineering to suit customer

Main Design Features

API 6D or API 6A

Metal Seat

ASME B16.34

Fire Safe

Full Bore

Bidirectional/Unidirectional

Self-Relieving

Anti-blow out stem

Anti-Static device

Standard-Reverse

Accessories

Vent & Drain

Plugged

Flanged

With valve

Any type of Connection Upon request

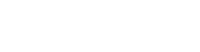

1. Through Conduit Slab GateValves API 6D

Features

Full bore | Pig gable | Double block and bleed, double isolation | Bubble tight | Bolted bonnet | Rising stem | Stem back-seat | Soft or metal seated

Applicable Standards

API 6D ISO 14316 | ANSI B16.34 | ANSI B16.10 | NACE MR0175 / ISO 150156

Range

2” to 42” Class 150 | 2” to 42” Class 300 | 2” to 42” Class 600 | 2” to 30” Class 900

Ends

Flanged to ANSI B16.5 - B16.47 - MSS SP-44 | Butt weld ends to ANSI B16.25

Materials

Carbon steel | Low temperature carbon steel | Stainless austenitic and super austenitic | Stainless duplex and super duplex | Nickel super alloys (Montel, Inconel 625, and Hastelloy)

Operators

Manual gear | Electric multi turn | Hy- draulic double acting and fail close | Pneumatic double acting and fail close

Options

Overlay Inconel 625 | Re- verse gate for fail close service | Inside screw

2. Through Conduit Double Expanding Gate Valves API 6D

Features

Full bore | Pig gable | Double block and bleed, double isolation | Bubble tight | Bolted bonnet | Rising stem | Soft or metal seated | Fire-safe | Fugitive emission

Applicable Standards

API 6D ISO 14316 | ANSI B16.34 | ANSI B16.10 | API 6FA | NACE MR0175 / ISO 150156

Range

2” to 42” Class 150 | 2” to 42” Class 300 | 2” to 42” Class 600 | 2” to 30” Class 900

Ends

Flanged to ANSI B16.5 - B16.47 - MSS SP- 44 | Hub connectors | Butt weld ends to ANSI B16.25

Materials

Carbon steel | Low temperature carbon steel | Stainless austenitic and super auste- nitic | Stainless duplex and super duplex, Nickel super alloys (Monel, Inconel 625, Hastelloy)

Operators

Manual gear | Electric multi turn | Hy- draulic double acting and fail close | Pneumatic double acting and fail close

Options

Inside screw | Overlay Inconel 625

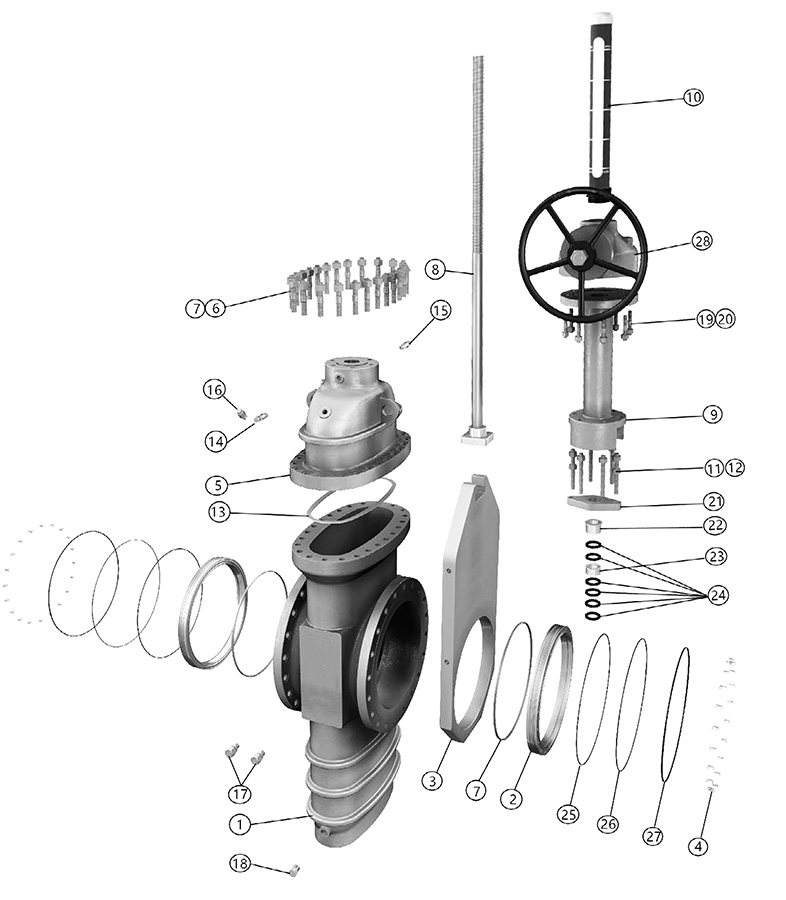

Item No. | Part Name | Item No. | Part Name |

|---|---|---|---|

1 | Body | 15 | Plug |

2 | Seat | 16 | Vent Valve |

3 | Disk | 17 | Injection Fitting |

4 | Spring | 18 | Drain Plug |

5 | Bonnet | 19 | Gearbox Stud Bolt |

6 | Bonnet Bolt | 20 | Gearbox Stud Nut |

7 | Bonnet Nut | 21 | Gland Flange |

8 | Stem | 22 | Gland |

9 | Welding Yoke | 23 | Lantern Ring |

10 | Stem Cover | 24 | Packing |

11 | Gland Stud Bolt | 25 | Graphite Wire Rod |

12 | Gland Stud Nut | 26 | Seat O-Ring |

13 | Gasket | 27 | Seat Gasket O-Ring |

14 | Packing Fitting | 28 | Gear Box |