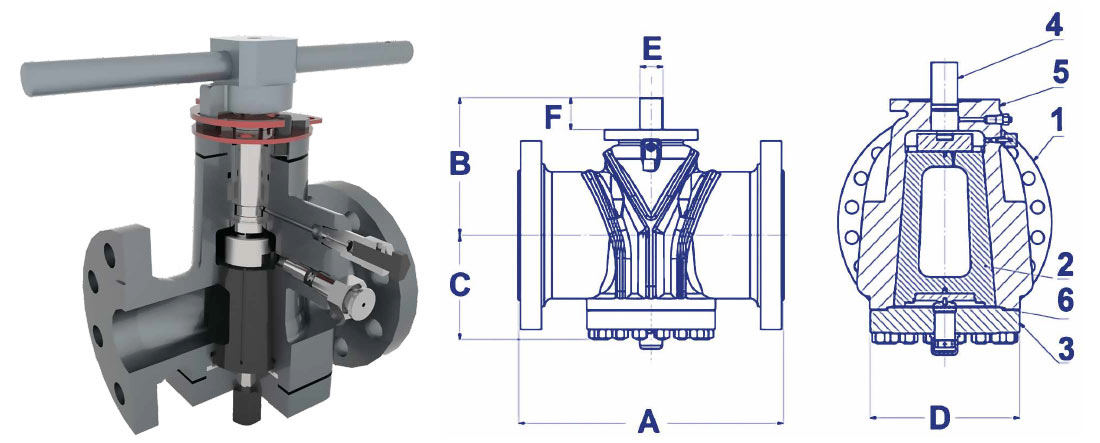

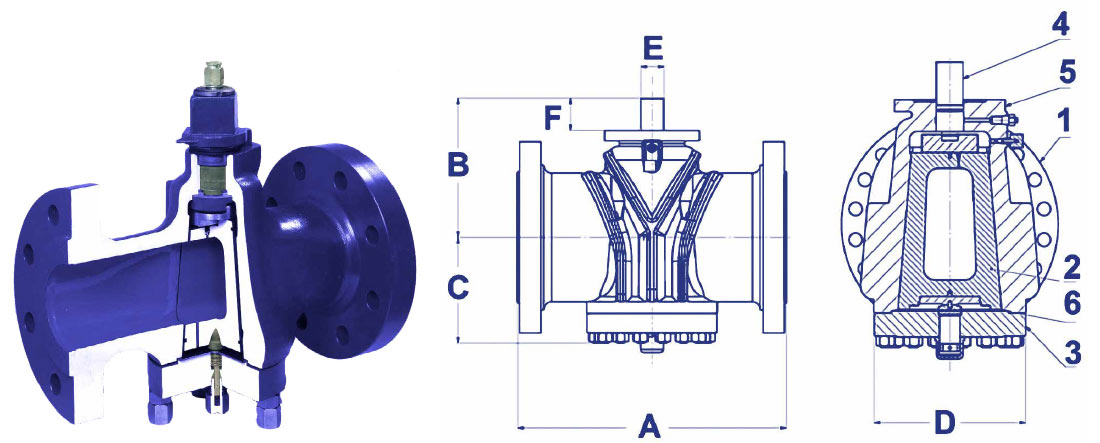

Pressure Balance Plug Valve

Use A Tapered Or Cylindrical Plug To Stop Or Start Flow.

To See More Details Download Catalog Below:

About Pressure Balance Plug Valve

A Plug Valve is a quarter-turn rotational motion Valve that use a tapered or cylindrical plug to stop or start flow. In the open position, the plug-passage is in one line with the inlet and outlet ports of the Valve body. If the plug 90° is rotated from the open position, the solid part of the plug blocks the port and stops flow. Plug valves are similar to Ball valves in operation.

Types of Plug valves

GAZAR Plug valves are available in a non-lubricated or lubricated design and with several styles of port openings. The port in the tapered plug is generally rectangular, but they are also available with round ports and diamond ports. Plug valves are also available with cylindrical plugs. The cylindrical plugs ensure greater port openings equal to or larger than the pipe flow area. GAZAR Lubricated Plug valves are provided with a cavity in the middle along there axis. This cavity is closed at the bottom and fitted with a sealant injection fitting at the top. The sealant is injected into the cavity, and a Check Valve below the injection Fitting prevents the sealant from flowing in the reverse direction. The lubricant in effect becomes a structural part of the Valve, as it provides a flexible and renewable seat. No lubricated Plug valves contain an elastomeric body liner or a sleeve, which is installed in the body cavity. The tapered and polished plug acts like a wedge and presses the sleeve against the body. Thus, the nonmetallic sleeve reduces the friction between the plug and the body.

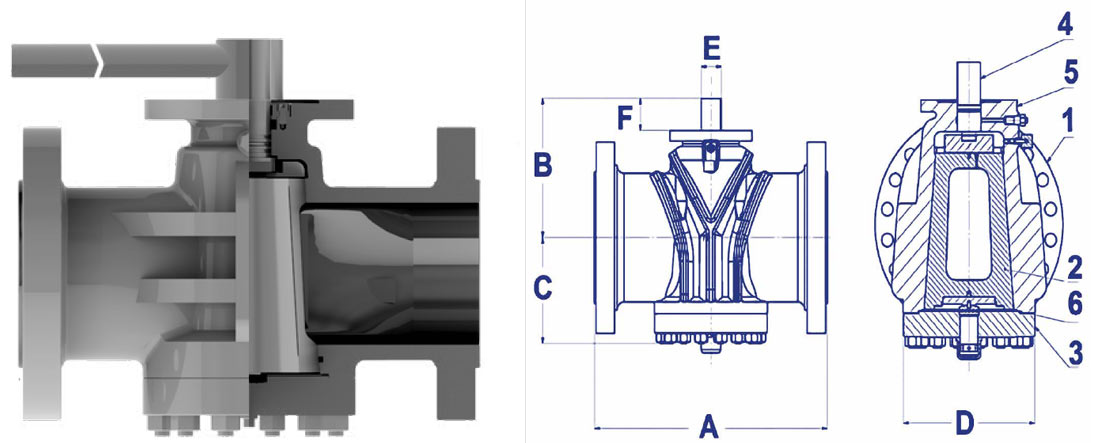

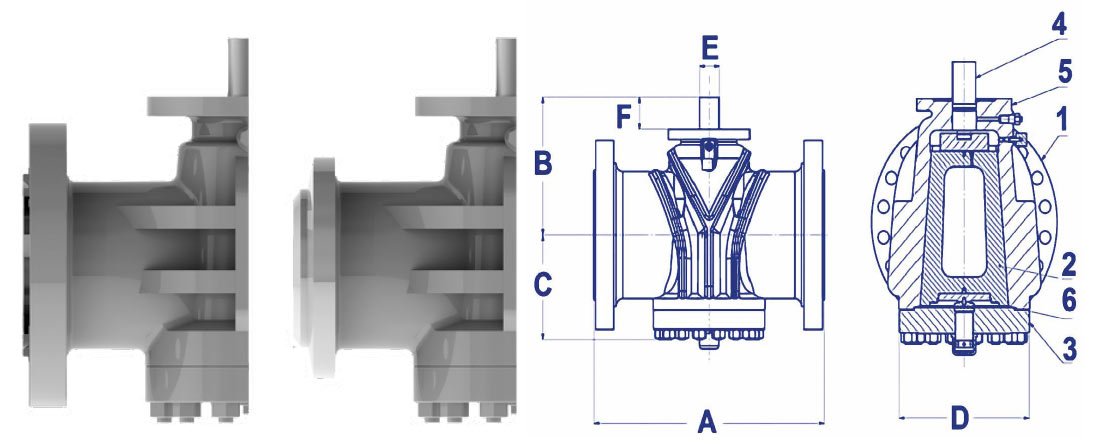

GAZAR Pressure Balance Plug Valve

Size | 2” – 24 “ |

Pressure Class | ASEM 150-2500 |

API Standard | API 6D, API 599 |

ASME | B16.10 & B16.5 & B 16.34 |

IGS | M-PL-02 |

Installation, Operating Instruction and Stress Analysis

Storage

1. Valves must be stored in a dry and ventilate room and placed orderly. The stem can’t bear any strength.

2. During the period of storage, the valve should be always on and inlet and outlet should be blocked.

3. During the period of storage, the outside portion of the stem and the machined surface should be covered

by an easily cleaned antirust.

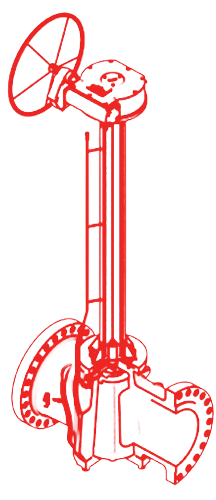

The Static Stress Analysis

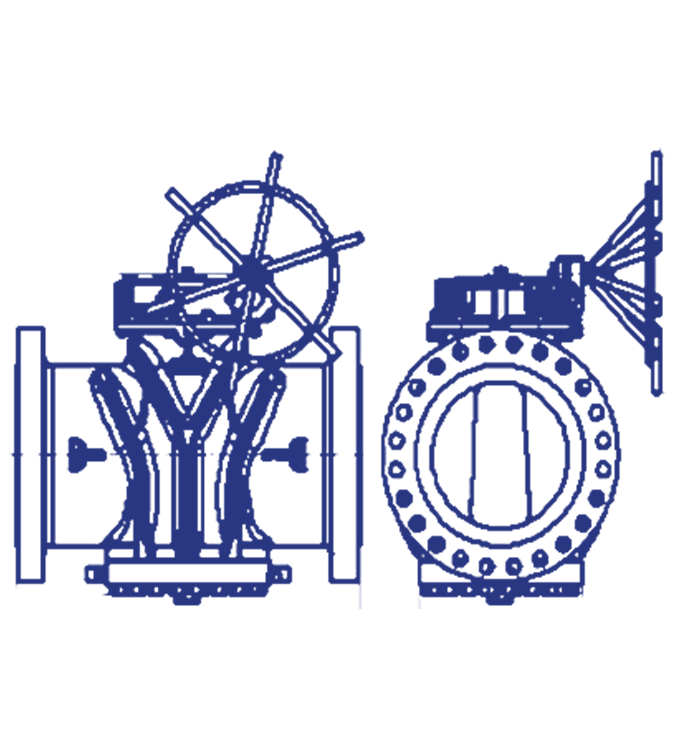

GAZAR Regular Pattern Plug Valve ANSI 150

Specifications: Reverse Type | Regular Pattern | Wrench Operated & Gear Operated | Lubricated taper Plug valve

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5, B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.10, API 599 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | ANSI API 6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Test according | API 598 & MSS. SP78 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Test | API 6FA | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GAZAR Regular Pattern Plug Valve ANSI 300

Specifications: Reverse Type | Regular Pattern | Wrench Operated & Gear Operated | Lubricated taper Plug valve

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5, B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.10, API 599 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | ANSI API 6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Test according | API 598 & MSS. SP78 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Test | API 6FA | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

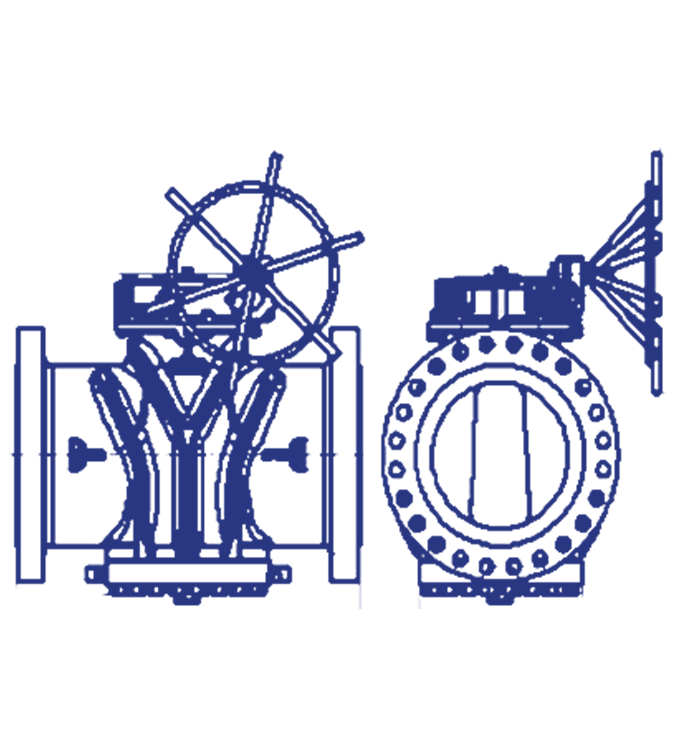

GAZAR Regular Pattern Plug Valve ANSI 600

Specifications: Reverse Type | Reduce Port; Regular | Lubricated taper Plug valve

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5, B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.10,API 6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | ANSI API 6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Test | ANSI API 6FA | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

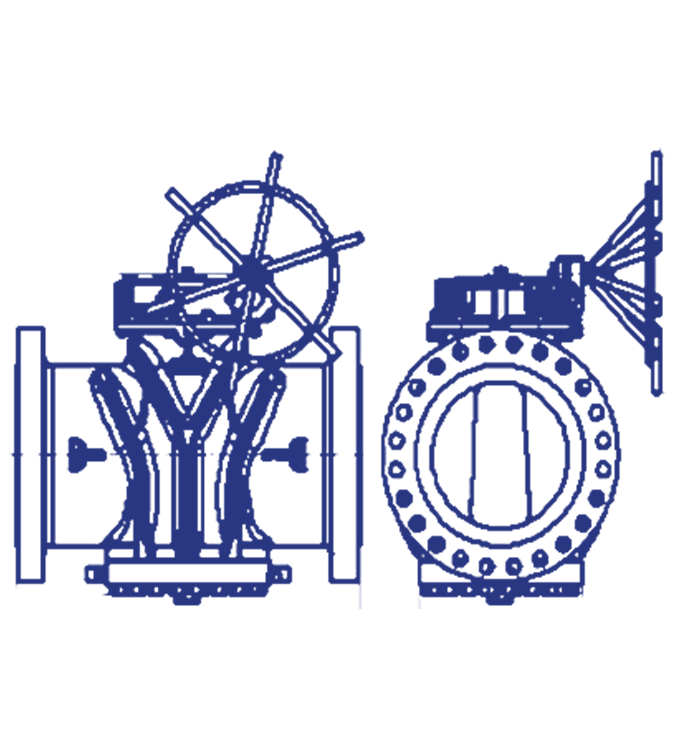

GAZAR Plug Valve Venturi Pattern ANSI 600

Specifications: Reverse Type | Reduce Port, Venturi | Lubricated taper Plug valve

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5, B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.10,API 6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | ANSI API 6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Safe Design | ANSI API 6FA | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

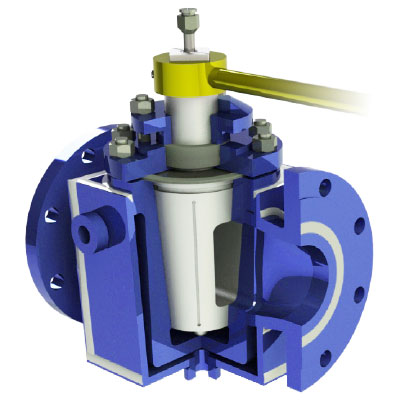

GAZAR Jacketed Short Pattern

Valves have face-to-face dimensions conforming to BS 5158 PN 10/16, BS 2080 class 150 Short, ANSI B16.10 & APR 6D Class 150 short. These valves are thus interchangeable with equivalent gate valves. Valves have pattern conforming to BS 5353, BS 5158, API 6D & API Short (with Steel Plug).

Valves are Normally supplied with drilled class 150 flange having serrated finish raised faces in accordance with ANSI B16.5 most valves on this page can be supplied with flange frillings to BS EN1092-1 PN16. Maximum pressure in jacket 150 lbf/in2 . Class 300 valves in size range 25mm to 100mm are available on request.

Jacketed valves with Oversize Flanges

Valves have face to-face dimension conforming to BS 5158 PN 10/16, BS 2080 class 150 short, ANSI B16.10 & API 6D class 150 short. These valves thus interchangeable with equivalent gate valves. Valves have conforming to BS 5353, BS5158, API 6D & API 599 short (with steel plug). Valves have face-to-face dimension confirming to BS EN 558 Basic Series-1. Valves are normally Supplied with drilled class 150 flanges having serrated finish faces in accordance with ANSI B16.5. Maximum pressure in Jacket 150 lbf/in2.

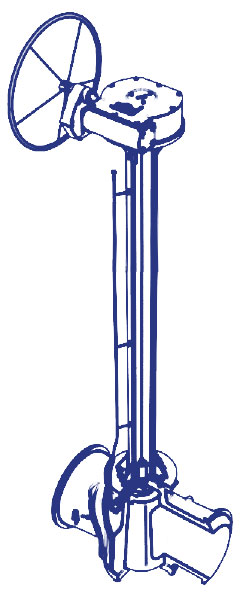

GAZAR Stem Extension Plug Valves

Extended Stem are made to be installed on wrench operated standard stems, in case of buried installation of the plug valve or in case of installation of the valve in plant locations where a normal access of man over is not possible.

Valve extension for underground service include piping for lubrication and are supplied with water tight seals. Extension length should be advised by customer.

Part Name | QTY | Material | Part Name | QTY | Material |

|---|---|---|---|---|---|

Body | 1 | Carbon Steel | Gland Packing | 2 | Grafoil |

Plug | 1 | Carbon Steel | Gland | 1 | Stainless Steel |

Stem | 1 | Stainless Steel | O-Ring (I) | 1 | Viton |

Cover | 1 | Carbon Steel | O-Ring (II) | 1 | Viton |

Cover Bolt | 1S | Carbon Steel | Lock Nut | 1 | Carbon Steel |

Lub. Nipple | 1 | Stainless Steel | Thrust Bearing | 1 | Stainless Steel |

Gland Bolt | 1S | Carbon Steel | Adjusting Bolt | 1 | Carbon Steel |

Press. Button | 1 | Stainless Steel | Lock Bolt | 1 | Carbon Steel |

Metal Diaphr’m (I) | 1 | Carbon Steel | Needle Valve | 1 | Carbon Steel |

Metal Diaphr’m (II) | 1 | Stainless Steel | Gear Opertator | 1S | Steel |

Gasket | 1 | Grafoil | Check Valve | 1 | Stainless Steel |

Check Valve | 1 | Stainless Steel | Pipe | 1 | Steel |

Compensator | 1 | Carbon Steel | Adapter | 1 | Steel |