Trunnion & Floating Ball Valves

Known for its robust design, sealing areas, and stainless steel overlays, pro- viding valve solutions for the oil and gas industries

To See More Details Download Catalog Below:

About Trunnion Ball Valves

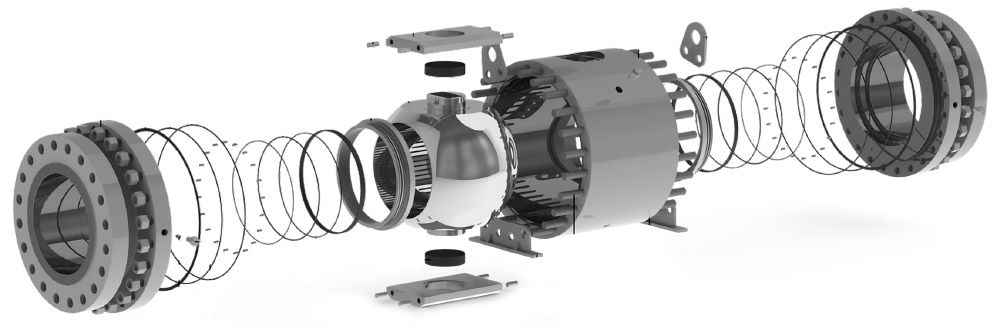

Trunnion ball valves have the obturator bounded by Trunnion which do not allow axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing. Trunnion standard construction ensures automatic cavity relief in case of overpressure in the body cavity; these valves can be selected for a wide range of applications with no specific limits to sizes and pressures.

GAZAR Trunnion Ball Valve Production are mainly designed to conform API 6D (Specification for pipeline valves) and ANSI B16.34 (Valves Flanged, Threaded and Welding End) or API 6A (Specification for Wellhead and Christmas Tree Equipment) in case of upstream applications. Other related standards such as ANSI B16.5 (Pipe Flanges and Flanged Fittings), ANSI B16.25 (Butt-welding Ends), and ANSI B16.10 (Face to Face and End-to-End Dimensions of Valves) are also used for the design of ball valves. Also our ball valves are designed to meet FIRE SAFE requirements to BS6755, API 6FA and API 607.

Final testing is done to conform API 598 (Valve Inspection and Testing) MSS-SP-61 (Pressure Testing of Steel Valves) API6D (Specification for Pipeline Valves) or API 6A (Specification for Wellhead and Christmas Tree Equipment) requirements. Materials are selected mainly to ASTM standards and when sour service is specified to meet NACE MR-01-75 (Sulfide Stress cracking resistanMetallic Materials for Oilfield Equipment).

Bi-directional Flow

GAZAR ball valves are suitable for bi-directional Sealing.

Soft Seated Valves

The seat design features a deep pocket with a protective lip which makes the design a long lasting design. The seat assembly consists in an outer metallic seat carrier with a soft seat insert. The soft insert is located into a groove in the metallic seat carrier. The complete seat assembly is floating inside valve body and it is energized by a set of springs which load the seat assembly against the ball preventing leakage from behind the seat.

Seat assembly is provided with outer O-ring to avoid leakage through the seat carrier and a graphite backup ring which ensure the tightness in case the O-ring is damaged.

Metal Seated Valves

Similar seat construction is done in case of metal seated valve. However the seat in this case consists only in a metallic seat ring (without any insert). The surface in contact with the ball is hard faced with Tungsten Carbide, stellite etc., achieving a minimum hardness of 42 HRC to stellite or convectional hard faced and 78 HRC to Tungsten Carbide or special hard faced. This makes the design long durable and reliable and able to achieve classes V & VI leakage class.

Trunnion Design for Low Torque Operation

Similar seat construction is done in case of metal seated valve. However the seat in this case consists only in a metallic seat ring (without any insert). The surface in contact with the ball is hard faced with Tungsten Carbide, stellite etc., achieving a minimum hardness of 42 HRC to stellite or convectional hard faced and 78 HRC to Tungsten Carbide or special hard faced. This makes the design long durable and reliable and able to achieve classes V & VI leakage class.

Stem Extension for Buried Service

A stem extension is a need when valves are being installed in underground pipeline making the valve operator non accessible. GAZAR offer a wide variety of stem extensions for manual operated valves as well as for actuated valves, including gas over-Oil operated valves. The stem extension includes the complete system of grease injection, actuator gas supply, etc. as a part of it.

Specification

Size Range: 2” – 56” | Pressure Class: ASME 150 – 900 API 2000 -15000 | API Standards: 6D & 6A | API 6D SS | ASME B16.34

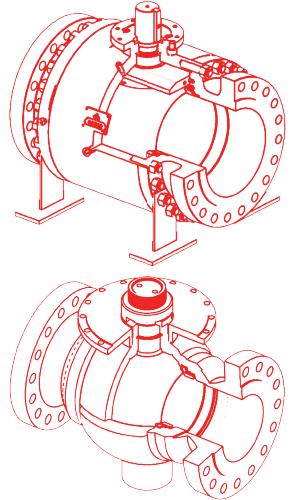

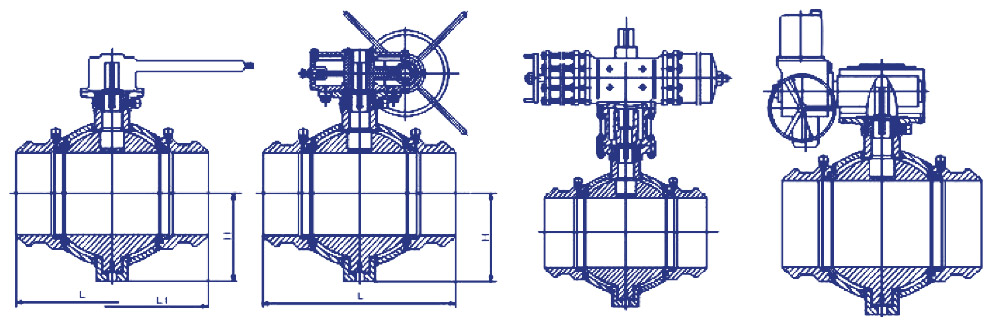

Fully Welded & Split Body Ball Valve

GAZAR Fully Welded & Split Body Valves are used in pipelines and pumping compression stations As well as subsea applications. Our welded design reduces the leakage path And makes the valves ideal for underground and subsea installations. Welding of the two or three piece body parts are performed with a special Technique so that post welding heat treatment is not required and soft Seals are not subject to damage during the welding. The extensive size range and pressure class are available in a Variety of materials including Carbon, Alloy & Stainless steel Suitable for general to severe service conditions. Our Split body design, size range and pressure class are Available in a variety of materials including Carbon, Alloy & Stainless steel suitable for general to severe serviceConditions.

• Size Range: 2” – 56”

• Pressure Class: ASME 150 – 900

• API Standards: 6D & 6DSS & 6A, ASME: B16.34

Features

Piece Body | Full And Reduced Bore | Trunnion Mounted | Double Block And Bleed | Single Or Double Piston Effect Design | Anti-blow Out Stem | Anti-static Device | Firesafe To Api-607 / 6FA / Iso 10497 | Spring Loaded Seats | Sealant Injection | Nace Mr-01-75

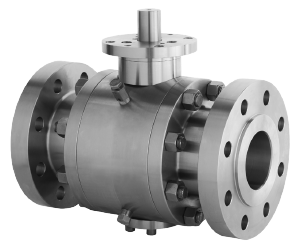

Top Entry Ball Valve

Top Entry Ball valves are used in pipelines, pumping and compression stations, offshore, onshore, subsea and cryogenic as well as Abrasive and high temp applications. The Top Entry design permits full repair in line and also allows the valve to be welded in line allowing easy maintenance. The cast or forged one piece body and bolted bonnet allows for the use of a full range of materials including Carbon, Alloy & Stainless steel suitable for general to severe service conditions.

Valve Material

GAZAR valves are manufactured using a wide selection of materials such as:

• Carbon steel

• Killed carbon steel for low temperature applications

• High resistance alloy steels for API 6A applications

• Stainless Steel

• Duplex & Super duplex steel

• Nickel alloys

Materials also meet the requirements of NACE MR-0175/ISO 15156 when sour gas services are specified. Our technical staff is ready and available to provide customized material selection for those special customer applications. GAZAR always provides the customer with suitable information of material selection which is agreed prior valves are manufactured.

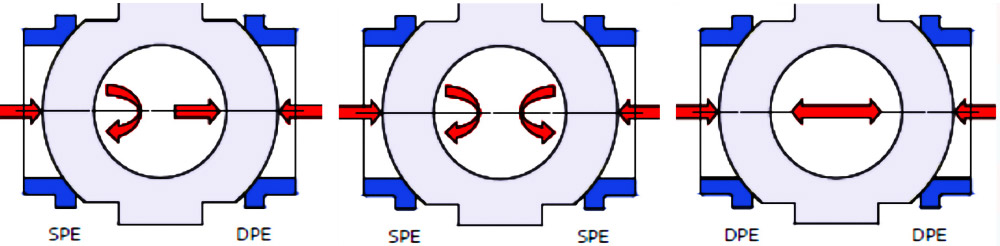

Seat Principle:

1. Two independent seat rings grant the sealing barrier against the line pressure acting on the upstream and downstream sides of the valve which allows the valve to be bidirectional. 2. A set of coil springs acting between the upstream side of each seat ring and the body, generate an uniform thrust on the seat which push the same against the ball and grant the sealing feature with no or very low pressure in the line, when the line pressure increase the thrust acting on the seat increases proportionally and the sealing feature is granted throughout the full pressure range. 3. The GAZAR trunnion mounted ball valves 4. Are available with Double Block & Bleed independent of the seat type.

Seat Design | Single Piston Effect (SPE) | Single Piston Effect (DPE) – DIB1 | Combined DIB1 |

|---|---|---|---|

Bi-Directional

Sealing | Yes | Yes | Yes |

Body-Cavity

Self-Relieving | Yes | No | Yes |

Double Barrier | No | No | Yes (Perferred Direction

Only) |

Single Piston Effect

Single piston effect (SPE) is the standard feature for the seat rings of the SADRA MAHAN PARSIAN (GAZAR) trunnion mounted ball valves. The pressure acting on the upstream side of the seat ring generates a force which push the seat towards the ball. The pressure acting on the downstream side of the seat ring generates a force which pull the seat ring away from the ball. Any overpressure which may be generated by the thermal expansion of the fluid trapped in the body cavity with the ball in fully closed position, will be automatically discharged in the line on the lower pressure side.

Double Piston Effect

Double piston effect (DPE) is a standard feature for the seat rings of the GAZAR trunnion mounted ball valves & recommended for welded body valves. On a DPE seat ring, both the pressure acting on the upstream side of the seat ring and the pressure acting on the downstream side of the seat ring, generate a force which push the seat towards the ball. With this type of seat ring, the eventual overpressure which may be generated by the thermal expansion of the fluid trapped in the body cavity with the ball in fully closed position, can be discharged by the use of, an external safety relief device. The Double Piston Effect grants a double sealing feature, if the upstream seat ring is damaged, the downstream seat grant the sealing feature of the valve.

Fire Safe

GAZAR complete range of Side entry, Top Entry and Welded body ball valves are certified fire safe according to API 607 / ISO 10497 – API 6 FA.

Valves Ends

Valves are available with:

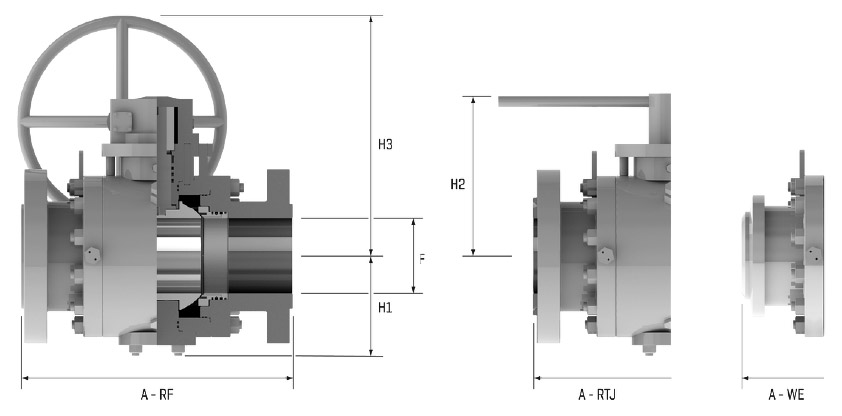

• Flanged Ends (RF or RTJ) to ASME B16.5 or ASME B16.47

• Welding Ends to ASME B16.25 Hub End

Bore

Valve can be supplied with Full or Reduced bore in accordance with table 1 of API 6D, unless otherwise required or advised. Valves with special Bore are available.

Face to Face/End to End

Dimensions are in accordance with API 6D and ASME B16.10. Special dimensions are available.

Valve Transition Pieces

Transition pieces (pups), can be supplied for Welding Ends Valves to facilitate the welding of the valve to the line for:

• Material compatibility.

• Excessive difference in strengths and thickness between valve closures and line pipe (limit is 1, 5 times).

• Avoiding damages to the valve soft seals.

Important note: when transition pieces are supplied by the customers, it is imperative to verify if the strength of the Same, suitable to undergo the hydrotest of the valve without damages or deformations (1.5 times the valve maximum rated pressure).

Weld Overlays

Welded overlays, with Stainless Steel, Duplex and Inconel are available on request for:

• All wetted parts

• Body wetted parts

• Seat rings housing pocket

• Stem sealing area

• Balls

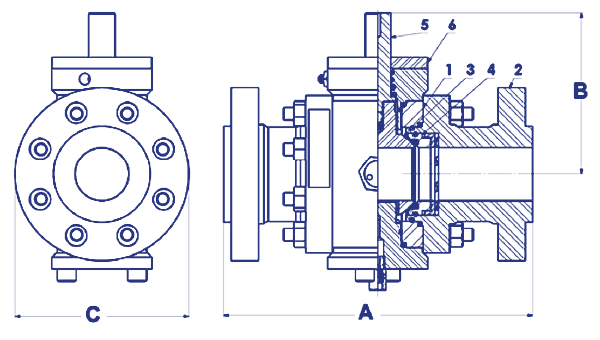

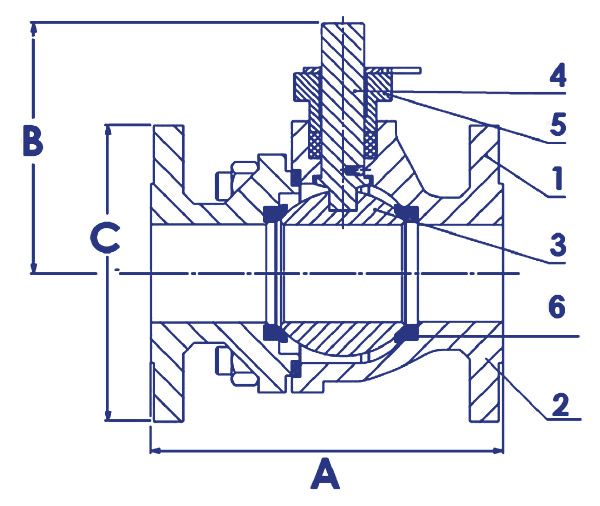

GAZAR Ball Valve Trunnion mounted (Double seat) (Size 1 ½” to 4”)

Specifications: Side Entry (3 Pieces) | Flanged Ends | Full Bore

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | API608 / API6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Safe Design | API607 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

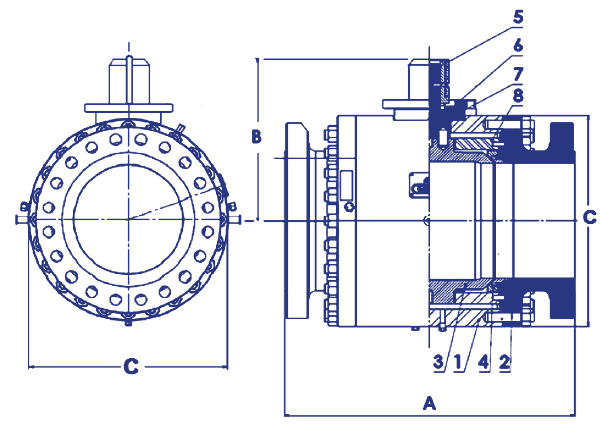

GAZAR Ball Valve Trunnion mounted (Double seat) (Size 6” to 60”)

Specifications: Side Entry (3 Pieces) | Flanged Ends | Full Bore

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.34,

ANSI B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | API608 / API6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Safe Design | API607 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

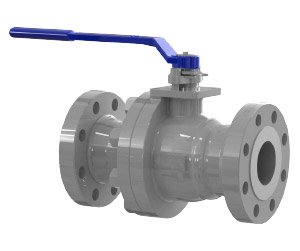

About Floating Ball Valve

GAZAR Floating Ball Valves are available in an extensive range of designs, materials, sizes and pressure classes and are in full conformance with ANSI, API and NACE specifications. All ball valves are designed in accordance with ASME B16.34 and API 608 and where applicable with API 6D or BS EN ISO 17292. GAZAR uses only high-quality materials inspected& tested to International Standards and utilizes advanced manufacturing technology with special emphasis on safety, quality, and long service life of our products, to ensure that our clients receive the “best in class” products available from us at a competitive price and delivered on time. Forging material has increased strength under maximum rated operation pressure compared with cast. Other forging properties include greater impact resistance, resistance to fatigue cracking, particularly when cycling at either high or Cryogenic temperature. Overdesigned wall thickness and adaptation of high strength tie bolts convenient for valve maintenance and sufficient pipe stress.

Ball valves are intended to be used as on/off flow control devices and are not to be used to throttle fluid flow. The valves should always be either fully open or closed.

GAZAR Floating Ball Valve design is developed using the latest software based analysis tools. At the design stage, all projects are analyzed using 3D solid modelling tools. Benefits include reduction of development time and cost, improved product quality, and ability to solve field problems for customers. Product flexibility and accuracy is assured.

Finite Element Analysis (FEA) is a very important step at the development stage to ensure the best possible performance requirements. Valves operational problems, pressure/temperature-related deformations and flow-related forces within a valve can be evaluated. GAZAR uses the FEA for predicting failure due to unknown stresses by showing problem areas in a material and allowing designers to see all of the theoretical stresses within.

Computational Fluid Dynamics (CFD) is used to simulate operating flow conditions. Evaluation of Valve CV coefficient and convective heat transfer coefficient takes place at the design stage.

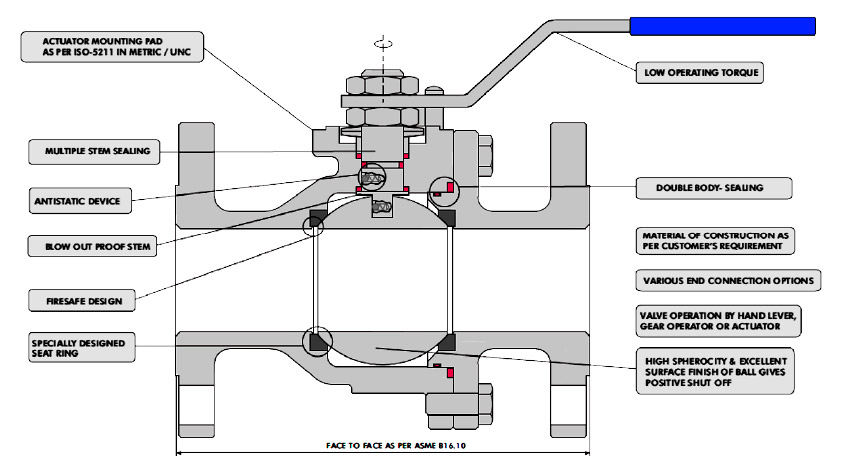

Main Features

• Fire-Safe Test Approved: GAZAR floating ball valves are designed in accordance with API 607 & API SPEC 6FA.

• Double Body Gasket

• Antic-Static Device

• Anti-Blow-Out Proof Stem

• Solid Ball

• Longevity of Life

• Low Torque Output

Inspection And Testing

Every valve is subjected on routine base to different non-destructive testing, like the dye penetrant test on butt weld ends, on all hard faced and cladding areas. Non-destructive test are also carried out on the critical areas as defined by ASME B16.34

Marking And Identification

Each valve is identified on proper name plate and on valve body as required by MSS SP-25 and ASME B16.34. Name plate carries all information on rating, size, valve body and trim material, customer tags.

Fire Safe

Fire safe Conformance to API 6FA/ API 607/BS-6755 part II Assures highest standard of safety. Certified by Customer’s Inspectors and independent certifying authorities.

GAZAR Ball Valve Floating (Double seat)

Specifications: Split Body | Flanged Ends | Full Bore

STANDARD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Face to Face Dimension | ANSI B16.10 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

End Flange Dimension | ANSI B16.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Design | ANSI B16.34 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Basic Design | API608 / API6D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fire Safe Design | API607 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||